Ka'idar jagorarmu ita ce mutunta ainihin ƙirar abokin ciniki yayin da muke ba da damar samar da mu don ƙirƙirar PCBs waɗanda ke cika ƙayyadaddun abokin ciniki. Duk wani canje-canje ga ƙirar asali na buƙatar amincewar rubuce-rubuce daga abokin ciniki. Bayan karɓar aikin samarwa, injiniyoyin MI suna bincikar duk takaddun da bayanan da abokin ciniki ya bayar. Suna kuma gano duk wani bambance-bambance tsakanin bayanan abokin ciniki da karfin samar da mu. Yana da mahimmanci don cikakkiyar fahimtar manufofin ƙira na abokin ciniki da buƙatun samarwa, tabbatar da cewa an fayyace duk buƙatun a sarari kuma ana iya aiwatar da su.

Inganta ƙirar abokin ciniki ya ƙunshi matakai daban-daban kamar zayyana tari, daidaita girman hakowa, faɗaɗa layin tagulla, haɓaka taga abin rufe fuska mai solder, gyaggyarawa haruffa akan taga, da aiwatar da ƙirar shimfidar wuri. Ana yin waɗannan gyare-gyare don daidaitawa tare da buƙatun samarwa da ainihin bayanan ƙira na abokin ciniki.

Tsarin ƙirƙirar PCB (Printed Circuit Board) na iya rushewa cikin matakai da yawa, kowanne ya ƙunshi fasahohin masana'antu iri-iri. Yana da mahimmanci a lura cewa tsarin yana bambanta dangane da tsarin allon. Matakai masu zuwa suna zayyana tsarin gaba ɗaya don PCB mai yawan Layer:

1. Yanke: Wannan ya haɗa da datsa zanen gado don haɓaka amfani.

2. Inner Layer Production: Wannan matakin shine farko don ƙirƙirar da'irar ciki na PCB.

- Pre-jiyya: Wannan ya ƙunshi tsaftacewa da PCB substrate surface da kuma cire duk wani surface gurɓatacce.

- Lamination: Anan, fim ɗin busassun yana manne da saman PCB, yana shirya shi don canja wurin hoto na gaba.

- Bayyanawa: Ƙaƙƙarfan mai rufi yana nunawa ga hasken ultraviolet ta amfani da kayan aiki na musamman, wanda ke canja wurin hoton substrate zuwa fim mai bushe.

- Sa'an nan kuma an haɓaka ƙwayar da aka fallasa, an cire shi, kuma an cire fim ɗin, yana kammala samar da katako na ciki.

3. Duban Ciki: Wannan mataki na farko shine don gwaji da kuma gyara da'irori na hukumar.

- Ana amfani da sikanin gani na AOI don kwatanta hoton allo na PCB tare da bayanan allo mai inganci don gano lahani kamar giɓi da ɓarna a cikin hoton allo. - Duk wani lahani da AOI ya gano sai ma'aikatan da suka dace su gyara su.

4. Lamination: Tsarin haɗuwa da yadudduka masu yawa a cikin allo guda.

- Browning: Wannan matakin yana haɓaka haɗin gwiwa tsakanin allon da guduro kuma yana inganta jigon saman jan ƙarfe.

- Riveting: Wannan ya haɗa da yanke PP zuwa girman da ya dace don haɗa katako na ciki tare da PP daidai.

- Latsa Zafi: Ana matse ruwan zafi kuma an ƙarfafa su cikin raka'a ɗaya.

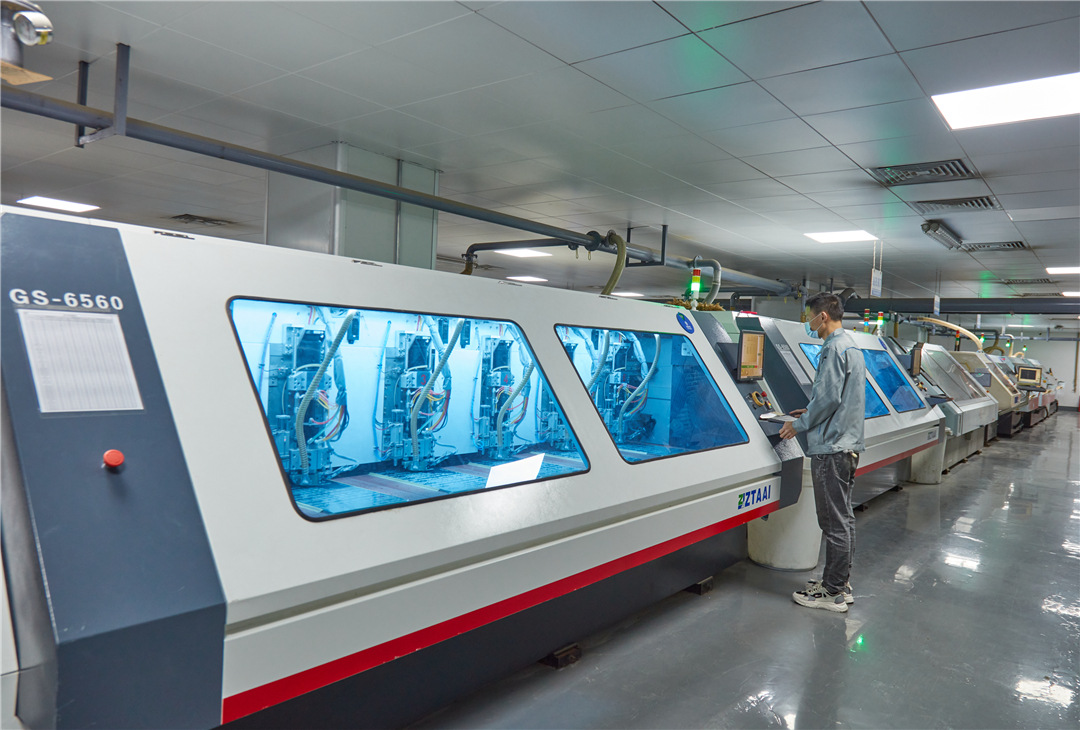

5. Drilling: Ana amfani da injin hakowa don ƙirƙirar ramuka na diamita daban-daban da girma akan allon kamar yadda bayanin abokin ciniki ya yi. Waɗannan ramukan suna sauƙaƙe sarrafa kayan aikin na gaba da taimako a cikin zubar da zafi daga allon.

6. Primary Copper Plating: Ramukan da aka haƙa a kan allo an yi su da tagulla don tabbatar da aiki a duk sassan allo.

- Deburring: Wannan mataki ya ƙunshi cire burrs a gefuna na allon rami don hana matalauta platin jan karfe.

- Cire Manne: Ana cire duk wani ragowar manne a cikin rami don haɓaka mannewa yayin micro-etching.

- Ramin Copper Plating: Wannan matakin yana tabbatar da haɓakawa a duk matakan jirgi kuma yana haɓaka kauri na tagulla.

7. Ƙirƙirar Layer na waje: Wannan tsari yana kama da tsarin Layer na ciki a mataki na farko kuma an tsara shi don sauƙaƙe ƙirƙirar da'ira na gaba.

- Pre-jiyya: Ana tsabtace saman allon ta hanyar pickling, niƙa, da bushewa don haɓaka busassun fim ɗin.

- Lamination: A bushe fim da aka manne da PCB substrate surface a shirye-shiryen ga m image canja wuri.

- Bayyanawa: Hasken hasken UV yana haifar da busassun fim a kan jirgin don shigar da yanayin polymerized da rashin amfani.

- Ci gaba: An narkar da fim ɗin busasshen da ba a yi amfani da shi ba, yana barin rata.

8. Secondary Copper Plating, Etching, AOI

- Sakonnin Copper Plating: Samfuran lantarki da aikace-aikacen tagulla ana yin su akan wuraren da ke cikin ramukan da busassun fim ɗin bai rufe su ba. Wannan matakin kuma ya ƙunshi ƙara haɓaka haɓaka aiki da kauri na tagulla, sannan kuma a saka kwano don kare amincin layin da ramuka yayin etching.

- Etching: Tushen jan ƙarfe a cikin fim ɗin busassun waje (fim ɗin rigar) an cire yankin abin da aka makala ta hanyar cire fim, etching, da aiwatar da cirewar kwano, yana kammala kewayen waje.

- Layer na waje AOI: Kamar Layer na ciki AOI, AOI na gani na gani ana amfani da shi don gano wuraren da ba su da lahani, wanda ma'aikatan da suka dace suka gyara su.

9. Solder Mask Application: Wannan mataki ya ƙunshi yin amfani da abin rufe fuska don kare allo da kuma hana oxidation da sauran batutuwa.

- Pretreatment: The jirgin shan pickling da ultrasonic wankewa don cire oxides da kuma ƙara jan karfe ta roughness.

- Buga: Ana amfani da tawada mai solder don rufe wuraren da PCB allon da ba ya buƙatar soldering, samar da kariya da rufi.

- Pre-baking: An bushe tawada a cikin tawada abin rufe fuska, kuma tawada yana taurare a shirye-shiryen fallasa.

- Bayyanawa: Ana amfani da hasken UV don warkar da tawada abin rufe fuska na solder, wanda ke haifar da samuwar babban polymer kwayoyin ta hanyar polymerization na hoto.

- Ci gaba: Ana cire maganin sodium carbonate a cikin tawada mara amfani.

- Bayan yin burodi: Tawada ya taurare sosai.

10. Rubutun Rubutu: Wannan matakin ya ƙunshi bugu rubutu a kan allon PCB don sauƙin tunani yayin tafiyar matakai masu zuwa.

- Pickling: Ana tsabtace saman allon don cire iskar shaka da haɓaka mannewar tawada.

- Buga Rubutu: Ana buga rubutun da ake so don sauƙaƙe hanyoyin walda masu zuwa.

11.Surface Jiyya: The danda jan karfe farantin undergoes surface jiyya bisa abokin ciniki bukatun (kamar ENIG, HASL, Azurfa, Tin, Plating zinariya, OSP) don hana tsatsa da hadawan abu da iskar shaka.

12.Board Profile: An tsara hukumar bisa ga bukatun abokin ciniki, sauƙaƙe SMT patching da taro.