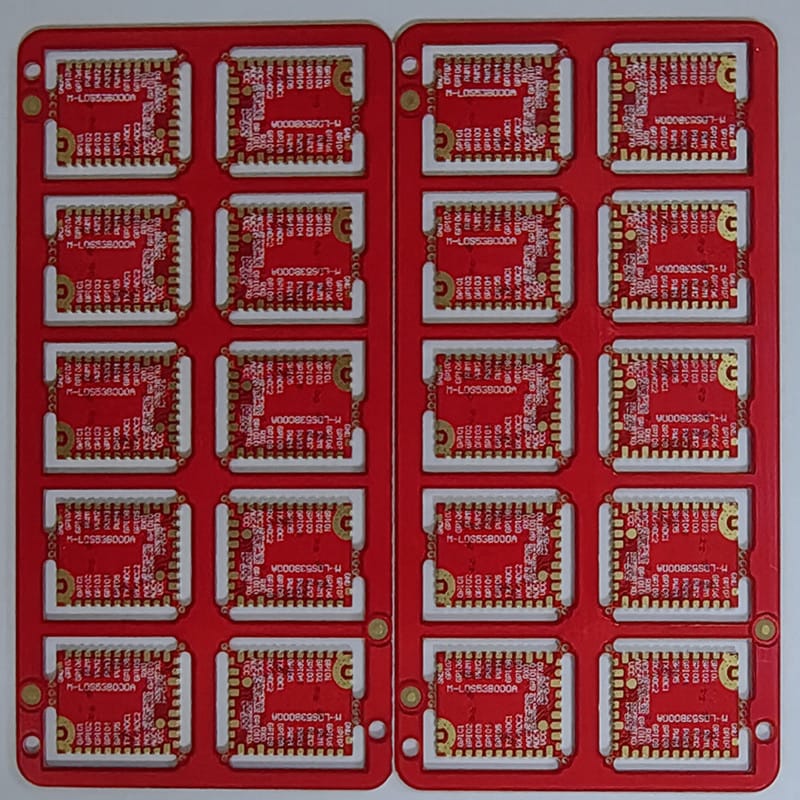

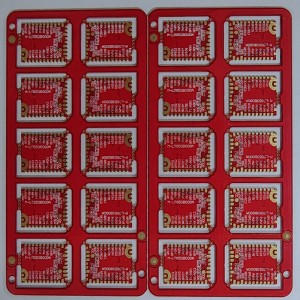

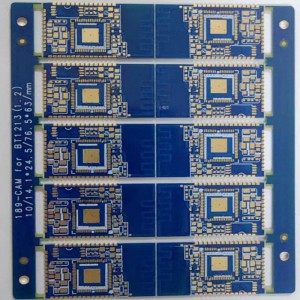

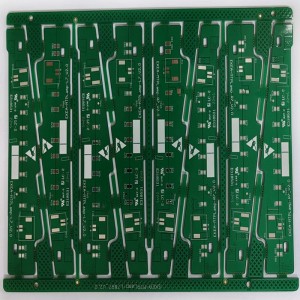

Samfurin buga allon da'ira RED solder abin rufe fuska ramukan castellated

Ƙayyadaddun samfur:

| Tushen Material: | Saukewa: FR4TG140 |

| Kauri PCB: | 1.0 +/- 10% mm |

| Ƙididdigar Layer: | 4L |

| Kaurin Copper: | 1/1/1/1 oz |

| Maganin saman: | ENIG 2U" |

| Mashin solder: | Ja mai sheki |

| Allon siliki: | Fari |

| Tsari na musamman: | Pth rabin ramukan akan gefuna |

Aikace-aikace

Hanyoyin plated rabin ramukan sune:

1. Gudanar da ramin gefen rabi tare da kayan yankan V-dimbin yawa.

2. Hasashen na biyu yana ƙara ramukan jagora a gefen ramin, yana cire fata na jan ƙarfe a gaba, yana rage bursu, kuma yana amfani da masu yankan tsagi maimakon rawar jiki don inganta saurin gudu da sauke gudu.

3. A nutsar da tagulla don sanya wutan lantarki, ta yadda wani Layer na tagulla ya zama electroplated akan bangon rami na ramin zagaye da ke gefen allo.

4. Samar da da'irar da'ira na waje bayan lamination, fallasa, da kuma ci gaban da substrate a jere, da substrate aka hõre ta biyu tagulla plating da tin plating, sabõda haka, da jan karfe Layer a kan ramin bango na zagaye rami a gefen allon da aka kauri da kuma tagulla Layer an rufe da wani tin Layer don lalata juriya;

5. Ƙirƙirar rabi-rami yanke ramin zagaye a gefen allon a rabi don samar da rabi;

6. A cikin mataki na cire fim din, an cire fim din anti-electroplating da aka danna yayin aikin fim din;

7. Etching da substrate an cire shi, kuma an cire tagulla da aka fallasa a saman Layer na ƙasa ta hanyar etching;

8. Ana cire tin ɗin da aka cire daga tin, don a iya cire tin da ke kan bangon rabin ramin, kuma a buɗe murfin tagulla a bangon rabin ramin.

9. Bayan ƙirƙirar, yi amfani da tef ɗin ja don haɗa allunan naúrar tare, kuma cire burrs ta hanyar layin etching na alkaline.

10. Bayan na biyu na jan karfe plating da tin plating a kan substrate, da zagaye rami a gefen allon da aka yanke da rabi don samar da rabin rami, domin tagulla Layer na ramin ramin Layer an rufe shi da wani tin Layer, da kuma jan Layer na ramin rami ne gaba daya m tare da tagulla Layer na waje Layer na substrate Connection, shafe karfi bonding ƙarfi, zai iya a kan yadda ya kamata a cire tagulla daga ramin da tagulla da ake cire daga tagulla Layer a lokacin da ya kamata a cire tagulla Layer daga tagulla.

11. Bayan da rabin-rami forming aka kammala, da fim da aka cire, sa'an nan etched, sabõda haka, da jan karfe surface ba za a oxidized, yadda ya kamata guje wa abin da ya faru na saura jan karfe ko ma short kewaye, da kuma inganta yawan amfanin ƙasa kudi na metallized rabin-rami PCB kewaye hukumar.

FAQs

Plated rabin-rami ko castellated-rami, shi ne gefu mai siffa ta tambari ta hanyar yankan cikin rabi akan shaci. Plated rabin rami shine matakin mafi girma na gefuna da aka zana don allon da'ira da aka buga, wanda galibi ana amfani da shi don haɗin jirgi-zuwa-jirgi.

Ana amfani da Via azaman haɗin kai tsakanin yadudduka tagulla akan PCB yayin da PTH gabaɗaya ana yin girma fiye da vias kuma ana amfani dashi azaman rami mai ɗorewa don karɓar jagorar abubuwan - kamar waɗanda ba SMT resistors, capacitors, da kunshin DIP IC. Hakanan za'a iya amfani da PTH azaman ramuka don haɗin injina yayin da ba zai yiwu ba.

Plating akan ramukan jan karfe ne, madugu, don haka yana ba da damar tafiyar da wutar lantarki ta cikin jirgi. Wadanda ba a rufe ta cikin ramuka ba su da motsi, don haka idan kun yi amfani da su, za ku iya samun waƙoƙin tagulla masu amfani kawai a gefe ɗaya na allon.

Akwai nau'ikan ramuka guda 3 a cikin PCB, Plated through Hole (PTH), Non-Plated Through Hole (NPTH) da Via Holes, bai kamata waɗannan su ruɗe da Slots ko Yankewa ba.

Daga ma'aunin IPC, shine +/- 0.08mm don pth, da +/- 0.05mm don npth.