Kayan aikin dakin gwaje-gwaje na jiki da sinadarai:

Gwajin injiniya, gwajin lantarki, dubawa da gwaji na farko, binciken dakin gwaje-gwaje.

1. Fage na tensile tester: An yi amfani da wannan kayan aikin don auna ƙarfi na tenalile da jan karfe na jan karfe yayin aiwatar da shimfiɗa. Yana taimakawa kimanta ƙarfi da taurin foil ɗin jan ƙarfe don tabbatar da ingancin samfur da amincin.

Gwajin Ƙarƙashin Ƙarƙashin Ƙarƙara

Injin Gwajin Gishiri Mai Cikakkiya Na atomatik

2. Na'urar gwajin gishiri mai cikakken hankali ta atomatik: Wannan injin yana simintin yanayin feshin gishiri don gwada juriyar lalata allon allon bayan jiyya. Yana taimakawa sarrafa ingancin samfurin kuma tabbatar da ingantaccen aiki a cikin yanayi mara kyau.

3. Na'urar gwaji ta waya guda hudu: Wannan kayan aikin yana gwada juriya da haɓakar wayoyi akan allon da aka buga. Yana ƙididdige aikin lantarki na hukumar, gami da aikin watsawa da amfani da wutar lantarki, don tabbatar da ingantaccen haɗin gwiwa da kwanciyar hankali.

Injin Gwajin Waya Hudu

4. Mai gwadawa na impedance: kayan aiki ne mai mahimmanci a cikin masana'anta da aka buga. Ana amfani da shi don auna ma'auni na impedance akan allon kewayawa ta hanyar samar da siginar AC mai kayyadadden lokaci wanda ke wucewa ta kewaye da ke ƙarƙashin gwaji. Da'irar ma'auni sannan tana ƙididdige ƙimar impedance bisa ka'idar Ohm da halaye na da'irori AC. Wannan yana tabbatar da cewa kwamitin da'ira da aka samar ya cika buƙatun impedance wanda abokin ciniki ya saita.

Masu masana'anta kuma za su iya amfani da wannan tsarin gwaji don yin gyare-gyaren tsari da haɓaka ikon sarrafa abubuwan da ke da alaƙa da allon kewayawa. Wannan ya zama dole don biyan buƙatun watsa siginar dijital mai sauri da aikace-aikacen mitar rediyo.

Mai gwadawa na impedance

A cikin tsarin samar da da'ira, ana gudanar da gwajin impedance a matakai daban-daban:

1) Matakin ƙira: Injiniya suna amfani da software na siminti na lantarki don tsarawa da tsara allon kewayawa. Suna yin ƙididdigewa da ƙididdige ƙimar impedance don tabbatar da cewa ƙirar ta cika takamaiman buƙatu. Wannan simintin yana taimakawa tantance impedance na allon kewayawa kafin masana'anta.

2) Matakin farko na masana'antu: Yayin samar da samfur, ana yin gwajin impedance don tabbatar da cewa ƙimar impedance ta yi daidai da tsammanin. Ana iya yin gyare-gyare ga tsarin masana'antu bisa waɗannan sakamakon.

3) Tsarin masana'antu: A cikin samar da allunan kewayawa da yawa, ana gudanar da gwajin impedance a cikin nodes masu mahimmanci don tabbatar da sarrafawa akan sigogi kamar kauri na tagulla, kauri na kayan dielectric, da faɗin layi. Wannan yana ba da tabbacin cewa ƙimar impedance ta ƙarshe ta cika buƙatun ƙira.

4) Duba samfurin da aka gama: Bayan masana'anta, ana gudanar da gwajin gwaji na ƙarshe akan allon kewayawa. Wannan yana tabbatar da cewa sarrafawa da gyare-gyare da aka yi a ko'ina cikin tsarin masana'antu yadda ya kamata ya dace da buƙatun ƙira don ƙimar impedance.

5. Na'urar gwajin ƙarancin juriya: Wannan injin yana gwada juriya na wayoyi da wuraren tuntuɓar a kan allon kewayawa don tabbatar da sun cika buƙatun ƙira da tabbatar da ingancin samfur da aiki.

Na'urar Gwajin ƙarancin juriya

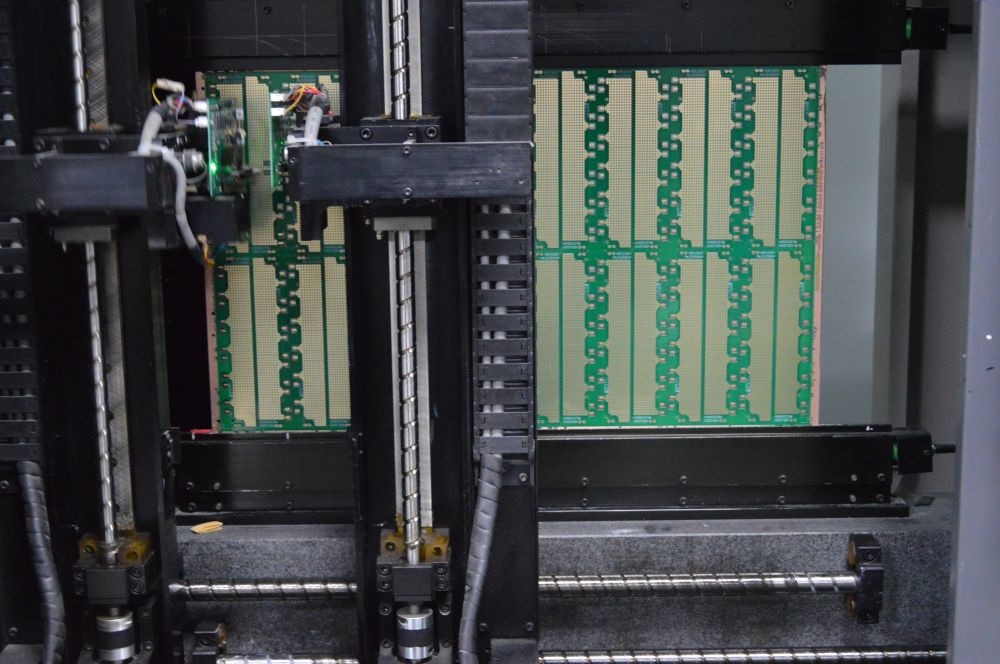

Gwajin Binciken Flying Probe

6. Gwajin bincike mai tashi: Ana amfani da gwajin gwaji mai tashi da farko don gwada insulation da ƙimar alƙaluman da'ira. Yana iya sa ido kan tsarin gwajin kuma gano makirufo a cikin ainihin lokaci, yana tabbatar da ingantaccen gwaji. Gwajin bincike na tashi ya dace da ƙananan ƙananan da matsakaita gwajin jirgi, saboda yana kawar da buƙatar gwajin gwajin, rage lokacin samarwa da farashi.

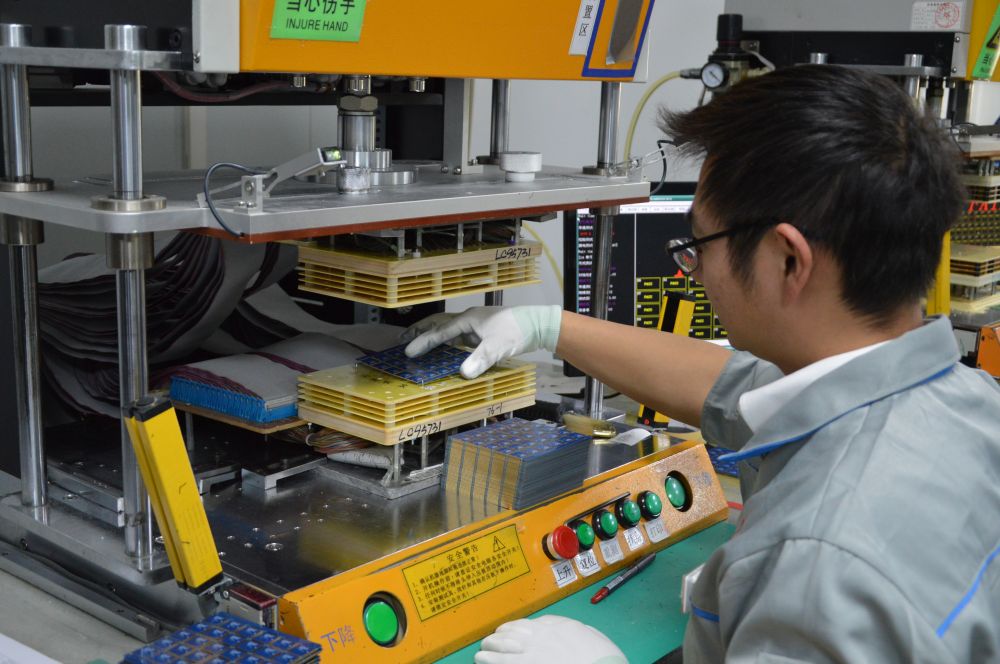

7. Fixture tooling tester: Mai kama da gwajin bincike na tashi, ana amfani da gwajin tararrakin gwaji don matsakaici da babban gwajin allo. Yana ba da damar gwaji na lokaci guda na maki gwaji da yawa, inganta ingantaccen gwaji da rage lokacin gwaji. Wannan yana haɓaka aikin gabaɗaya na layin samarwa, yayin da tabbatar da daidaito da sake amfani da su sosai.

Gwajin Kayan Aikin Kaya na Manual

Gwajin Kayan Aikin Kaya ta atomatik

Shagon Kayan Kayan Aiki

8. Na'urar auna nau'i biyu: Wannan kayan aikin yana ɗaukar hotunan saman abu ta hanyar haskakawa da daukar hoto. Daga nan sai ta aiwatar da hotuna tare da nazarin bayanan don samun bayanan geometric game da abu. Ana nuna sakamakon a gani, ba da damar masu aiki su lura da kuma auna daidai siffar, girman, matsayi, da sauran halayen abu.

Kayan Aunawa Mai Girma Biyu

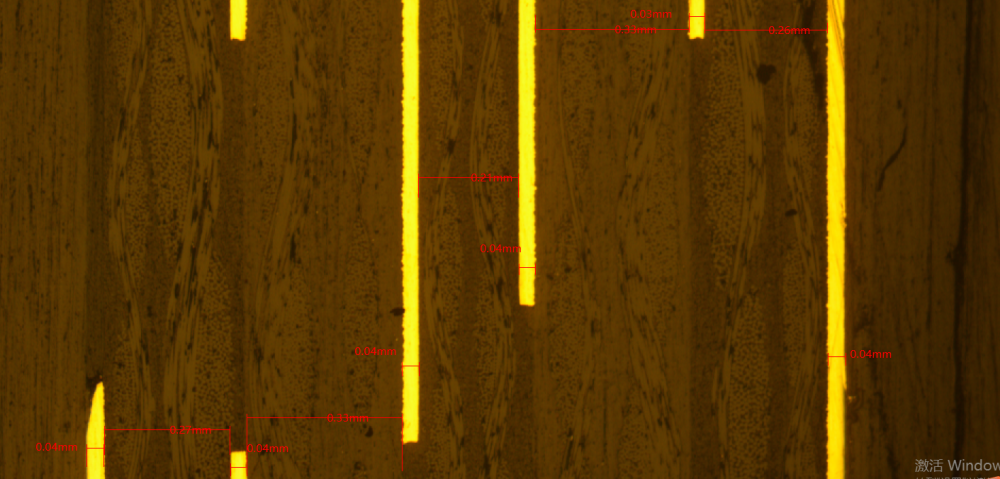

Kayan Aunawa Faɗin Layi

9. Line nisa ma'auni kayan aiki: The line nisa ma'auni kayan aiki ne da farko amfani da su auna babba da ƙananan nisa, yanki, kwana, da'irar diamita, da'irar cibiyar nesa, da sauran sigogi na buga kewaye hukumar ta Semi kammala kayayyakin bayan ci gaba da etching (kafin buga solder mask tawada). Yana amfani da tushen haske don haskaka allon kewayawa kuma yana ɗaukar siginar hoto ta hanyar haɓakawa na gani da canza siginar hoto na CCD. Ana nuna sakamakon ma'aunin akan hanyar sadarwa ta kwamfuta, yana ba da damar yin daidai da ingantaccen ma'auni ta danna kan hoton.

10. Tin makera: The tin makera da ake aiki don gwada solderability da thermal girgiza juriya na kewaye allon, tabbatar da inganci da amincin solder gidajen abinci.

Gwajin solderability: Wannan yana kimanta ikon saman allon kewayawa don samar da amintattun solder shaidu. Yana auna wuraren tuntuɓar don tantance haɗin kai tsakanin kayan solder da saman allon kewayawa.

Gwajin juriya na zafi mai zafi: Wannan gwajin yana tantance juriyar hukumar kewayawa ga bambancin yanayin zafi a cikin mahalli masu zafi. Ya ƙunshi fallasa allon kewayawa zuwa yanayin zafi da sauri da canja shi zuwa ƙananan yanayin zafi don kimanta juriyar girgizawar zafi.

11. Injin duba X-ray: Na'urar duba X-ray tana da ikon shiga allunan da'ira ba tare da buƙatar tarwatsawa ko haifar da lalacewa ba, don haka guje wa yuwuwar farashi da lalacewa. Yana iya gano lahani a kan allon kewayawa, gami da ramukan kumfa, buɗaɗɗen da'irori, gajerun kewayawa, da layukan da ba su da kyau. Kayan aiki yana aiki da kansa, ta atomatik lodi da sauke kayan aiki, ganowa, nazari, da ƙayyade rashin daidaituwa, da kuma yin alama ta atomatik da lakabi, don haka inganta ingantaccen samarwa.

Injin duba X-ray

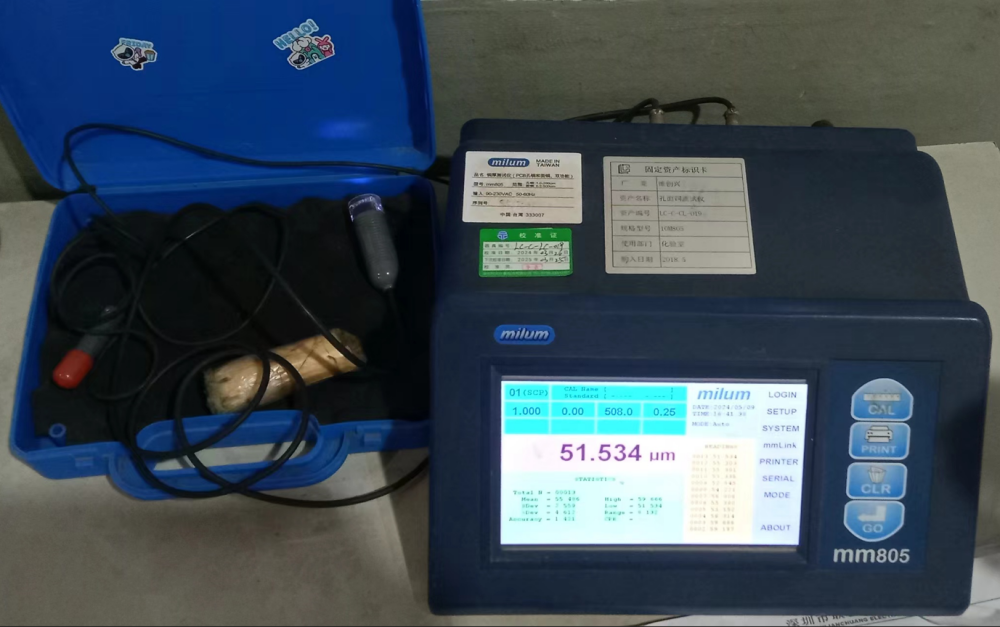

Rufe Kauri Ma'aunin

12. Rufe kauri ma'auni: A lokacin da masana'antu tsari na kewaye allon, daban-daban coatings (kamar da tin plating, zinariya plating, da dai sauransu) sau da yawa amfani da inganta conductivity da lalata juriya. Koyaya, kauri mara kyau zai iya haifar da al'amuran aiki. Ana amfani da ma'aunin kauri don auna kauri na rufin akan farfajiyar hukumar kewayawa, tabbatar da ya dace da buƙatun ƙira.

13. Kayan aikin ROHS: A cikin samar da allunan da'ira da aka buga, ana amfani da kayan aikin ROHS don ganowa da bincika abubuwa masu cutarwa a cikin kayan, tabbatar da bin ka'idodin umarnin ROHS. Umurnin ROHS, wanda Tarayyar Turai ta aiwatar, yana ƙuntata abubuwa masu haɗari a cikin kayan lantarki da lantarki, gami da gubar, mercury, cadmium, chromium hexavalent, da sauransu. Ana amfani da kayan aikin ROHS don auna abubuwan da ke cikin waɗannan abubuwa masu cutarwa, tabbatar da cewa kayan da aka yi amfani da su a cikin tsarin kera na kwalayen da'irar bugu sun cika buƙatun umarnin ROHS, tabbatar da amincin samfura da kariyar muhalli.

Bayani: ROHS Instrument

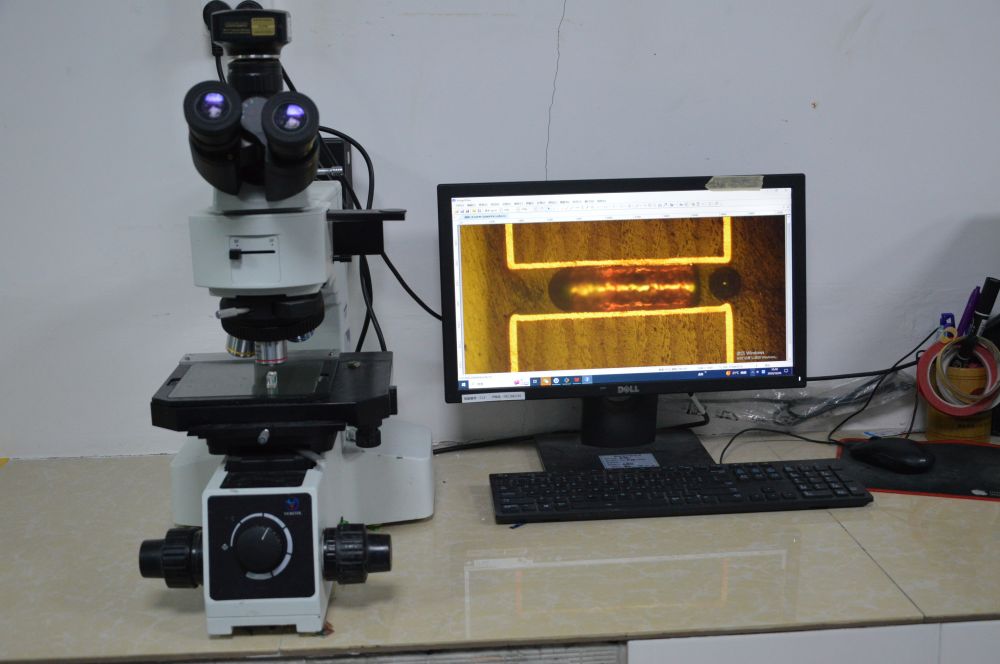

14. Metallographic microscope: The metallographic microscope ne da farko ana amfani da shi don bincika kauri na jan karfe na ciki da waje yadudduka, electroplated saman, electroplated ramukan, solder masks, surface jiyya, da kuma kauri na kowane dielectric Layer saduwa abokin ciniki bayani dalla-dalla.

Ma'ajiyar Kayayyakin Kaya

Karamin Sashe na 1

Karan gani da ido Sashi na 2

Hole Surface Copper Gwajin

15. Hole surface jan karfe tester: Ana amfani da wannan kayan aikin don gwada kauri da daidaiton foil ɗin tagulla a cikin ramukan da aka buga da'ira. Ta hanyar gano ƙayyadaddun kauri na tagulla da sauri ko karkacewa daga keɓaɓɓen jeri, ana iya yin gyare-gyare ga tsarin samarwa cikin kan kari.

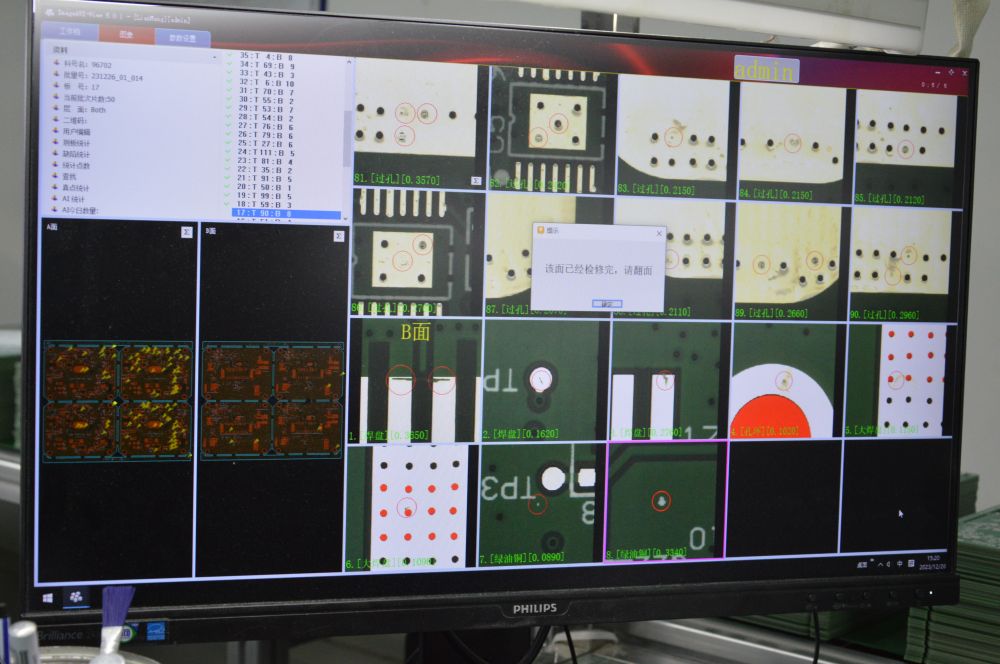

16. Scanner na AOI, gajere don Inspection Optical Inspection, wani nau'in kayan aiki ne wanda ke amfani da fasahar gani don gano abubuwan haɗin lantarki ta atomatik ko samfuran. Ayyukansa sun haɗa da ɗaukar hoton saman abin da ake dubawa ta amfani da tsarin kyamara mai ƙima. Bayan haka, ana amfani da fasahar sarrafa hoton kwamfuta don tantancewa da kwatanta hoton, wanda ke ba da damar gano lahani na saman da kuma lalata al'amurran da suka shafi abin da aka nufa.

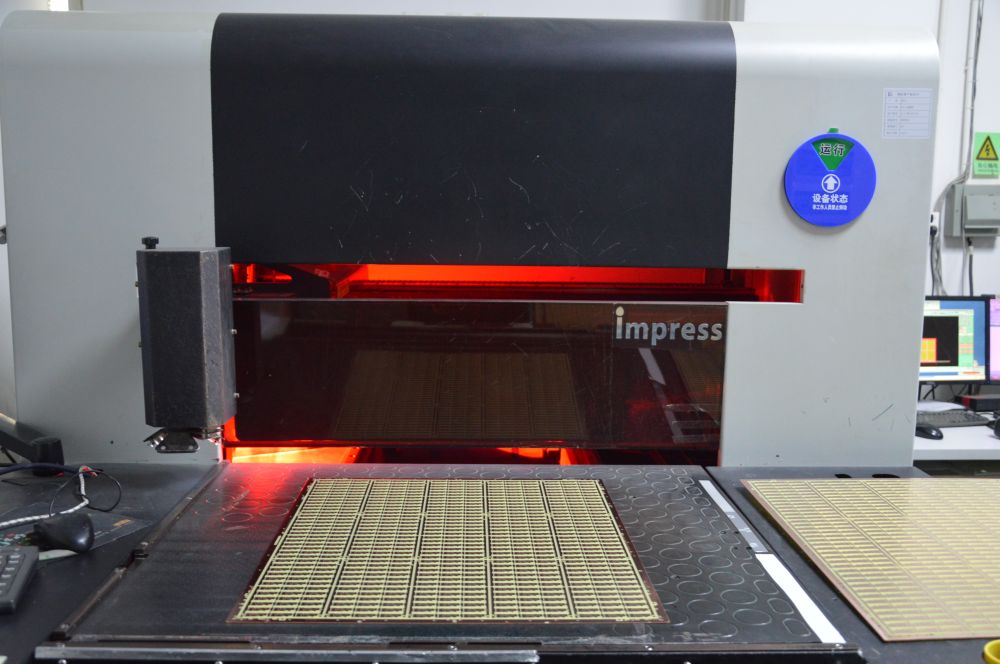

AOI Scanner

17. Na'urar duba bayyanar PCB ita ce na'urar da aka tsara don tantance ingancin gani na allon kewayawa da kuma gano lahani na masana'antu. Wannan na'ura tana da babban kyamarar kyamara da tushen haske don gudanar da cikakken bincike na saman PCB, gano lahani iri-iri kamar karce, lalata, gurɓatawa, da al'amurran walda. Yawanci, ya haɗa da tsarin ciyarwa ta atomatik da sauke kaya don sarrafa manyan batches na PCB da keɓance allunan da aka amince da ƙima. Ta hanyar amfani da algorithms sarrafa hoto, an ware lahani da kuma yiwa alama alama, yana sauƙaƙa da ƙarin daidaitattun gyare-gyare ko kawarwa. Godiya ga ci-gaba da iya sarrafa hoto, waɗannan injunan suna gudanar da bincike da sauri, suna haɓaka aiki da yanke farashi. Bugu da ƙari kuma, za su iya adana sakamakon dubawa da kuma samar da cikakkun rahotanni don ingantacciyar kulawa da haɓaka tsari, a ƙarshe suna haɓaka ingancin samfur.

Injin Duba Bayyanuwa 1

Injin Binciken Bayyanar 2

Lalacewar Duban Bayyanar Alama

Gwajin Gurbacewar PCB

18. The PCB ion contamination tester ne na musamman kayan aiki da ake amfani da su domin gano ion gurbatawa a buga kewaye allon (PCBs). A lokacin aikin kera kayan lantarki, kasancewar ions akan saman PCB ko a cikin jirgi na iya tasiri sosai akan ayyukan kewayawa da ingancin samfur. Don haka, ainihin ƙima na matakan gurɓataccen ion akan PCBs yana da mahimmanci don tabbatar da inganci da dogaron kayan lantarki.

19. An yi amfani da na'ura mai ba da wutar lantarki mai amfani da wutar lantarki don gudanar da gwaje-gwajen ƙarfin lantarki don tabbatar da cewa kayan haɓakawa da tsarin tsarin tsarin kewayawa suna bin daidaitattun ƙayyadaddun bayanai. Wannan yana tabbatar da cewa hukumar da'irar ta kasance a killace a ƙarƙashin yanayin aiki na yau da kullun, yana hana yuwuwar gazawar rufin da zai haifar da haɗari masu haɗari. Ta hanyar nazarin sakamakon gwajin, za a iya gano duk wata matsala da ke da alaƙa da hukumar da'ira da sauri, tana jagorantar masu ƙira wajen haɓaka tsarin hukumar da tsarin rufewa don haɓaka inganci da aikinta.

Injin Gwajin Insulation Voltage

UV Spectrophotometer

20. UV spectrophotometer: Ana amfani da UV spectrophotometer don auna halayen ɗaukar haske na kayan ɗaukar hoto da aka yi amfani da su zuwa allon kewayawa. Waɗannan kayan, yawanci masu ɗaukar hoto da ake amfani da su wajen kera kwalayen da'irar da aka buga, suna da alhakin ƙirƙirar ƙira da layi akan allunan.

Ayyukan UV spectrophotometer sun haɗa da:

1) Ma'auni na halayen ɗaukar haske na photoresist: Ta hanyar nazarin halayen shayarwa na photoresist a cikin kewayon ultraviolet bakan, za'a iya ƙayyade matakin ɗaukar haske na ultraviolet. Wannan bayanin yana taimakawa wajen daidaita tsari da kauri na mai ɗaukar hoto don tabbatar da aikin sa da kwanciyar hankali yayin daukar hoto.

2) Ƙaddamar da ma'auni na bayyanar hoto: Ta hanyar nazarin halayen halayen haske na photoresist, za'a iya ƙayyade ma'auni mai kyau na hotuna, irin su lokacin bayyanar da hasken haske. Wannan yana tabbatar da daidaitaccen kwafi na alamu da layukan kan mai ɗaukar hoto daga allon kewayawa.

21. pH mita: A cikin masana'antu tsari na kewaye allon, sunadarai jiyya kamar pickling da alkali tsaftacewa yawanci aiki. Ana amfani da mita pH don tabbatar da cewa ƙimar pH na maganin maganin ya kasance cikin kewayon da ya dace. Wannan yana tabbatar da inganci, aiki, da kwanciyar hankali na maganin sinadarai, ta haka inganta ingancin samfur da aminci yayin tabbatar da yanayin samar da lafiya.