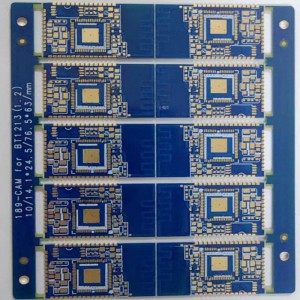

Pcb samfur pcb ƙirƙira blue solder abin rufe fuska plated rabin ramuka

Ƙayyadaddun samfur:

| Tushen Material: | Saukewa: FR4TG140 |

| Kauri PCB: | 1.0 +/- 10% mm |

| Ƙididdigar Layer: | 2L |

| Kaurin Copper: | 1/1 oz |

| Maganin saman: | ENIG 2U" |

| Mashin solder: | Shuɗi mai sheki |

| Allon siliki: | Fari |

| Tsari na musamman: | Pth rabin ramukan akan gefuna |

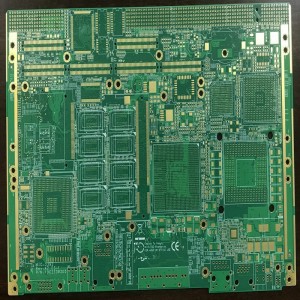

Aikace-aikace

PCB rabin rami allo yana nufin hakowa na biyu da tsarin tsari bayan an huda rami na farko, kuma a ƙarshe an tanadi rabin ramin ƙarfe. Manufar ita ce a haɗa gefen rami kai tsaye zuwa babban gefen don adana masu haɗawa da sarari, kuma sau da yawa yana bayyana a cikin sigina.

Ana amfani da allunan da'irar rabi-rami don hawa manyan abubuwan lantarki masu yawa, irin su na'urorin hannu, agogo mai kaifin baki, kayan aikin likitanci, kayan sauti da bidiyo, da sauransu. Suna ba da damar mafi girman kewayawa da ƙarin zaɓuɓɓukan haɗin kai, yin na'urorin lantarki ƙarami, haske da inganci.

Ramin rabin ramin da ba a rufe ba a gefuna na PCB yana ɗaya daga cikin abubuwan ƙira da aka saba amfani da su a cikin tsarin masana'antar PCB, kuma babban aikinsa shine gyara PCB. A cikin tsarin samar da hukumar PCB, ta hanyar barin rabin ramuka a wasu wurare a gefen allon PCB, ana iya daidaita allon PCB akan na'urar ko gidaje tare da sukurori. A lokaci guda kuma, yayin tsarin taron kwamitin PCB, rabin rami shima yana taimakawa wajen daidaitawa da daidaita allon PCB don tabbatar da daidaito da kwanciyar hankali na samfurin ƙarshe.

Rabin ramin da aka sanya a gefen allon kewayawa shine don inganta amincin haɗin haɗin gefen allon. Yawancin lokaci, bayan an gyara allon da aka buga (PCB), za a fallasa Layer na jan karfe da aka fallasa a gefen, wanda ke da haɗari ga oxidation da lalata. Don magance wannan matsala, ana yawan lulluɓe Layer ɗin tagulla a cikin Layer na kariya ta hanyar sanya electroplating gefen allon zuwa cikin rami na rabi don inganta juriya na oxygenation da juriya na lalata, kuma yana iya ƙara wurin walda da inganta amincin haɗin.

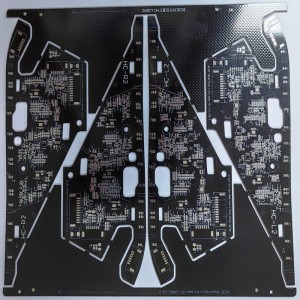

A cikin aikin sarrafawa, yadda za a sarrafa ingancin samfurin bayan samar da ramuka na karfe a gefen allo, kamar ƙaya na tagulla a bangon ramin, da dai sauransu, ya kasance matsala mai wuyar gaske a cikin aikin sarrafawa. Don irin wannan nau'in jirgi mai jeri na ramukan da aka yi da ƙarfe-karfe na PCB yana da ɗan ƙaramin diamita, kuma galibi ana amfani da shi don hukumar 'yar uwar hukumar. Ta waɗannan ramukan, ana haɗa shi tare da allon uwar da fitilun abubuwan da aka haɗa. Lokacin saida, zai kai ga rauni mai rauni, siyarwar karya, da gajeriyar da'ira tsakanin fil biyu.

FAQs

Yana iya zama da amfani a sanya ramukan plated (PTH) a gefen allo. Misali lokacin da kake son siyar da PCB biyu akan juna a kusurwar 90° ko kuma lokacin sayar da PCB zuwa casing na ƙarfe.

Misali, haɗe-haɗe na rikitattun kayayyaki na microcontroler tare da na gama-gari, waɗanda aka ƙera PCBs daban-daban.Ƙarin aikace-aikace nuni ne, HF ko na'urorin yumbu waɗanda aka siyar da su zuwa allon da'irar da aka buga.

Drilling- plated ta rami (PTH) - panel plating - image canja wuri - juna plating -pth rabin rami - tsiri - etching - solder mask - silkscreen - surface jiyya.

1.Diamita ≥0.6MM;

2.Nisa tsakanin ramin rami ≥0.6MM;

3. Nisa na etching zobe yana buƙatar 0.25mm;

Rabin rami tsari ne na musamman. Domin tabbatar da cewa akwai jan karfe a cikin rami, dole ne a fara niƙa gefen kafin a sanya aikin tagulla. PCB mai rabin ramin gabaɗaya kaɗan ne, don haka farashin sa ya fi PCB na gama-gari tsada.