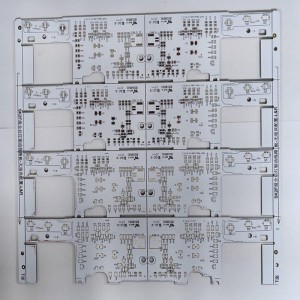

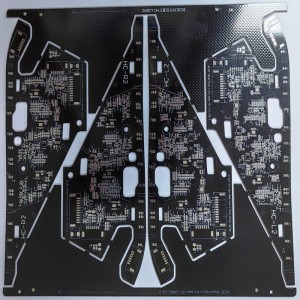

Multi kewaye allon TG150 8 yadudduka

Ƙayyadaddun samfur:

| Tushen Material: | Saukewa: FR4TG150 |

| Kauri PCB: | 1.6 +/- 10% mm |

| Ƙididdigar Layer: | 8L |

| Kaurin Copper: | 1 oz ga duk yadudduka |

| Maganin saman: | HASL-LF |

| Mashin solder: | Koren mai sheki |

| Silkscreen: | Fari |

| Tsari na musamman: | Daidaitawa |

Aikace-aikace

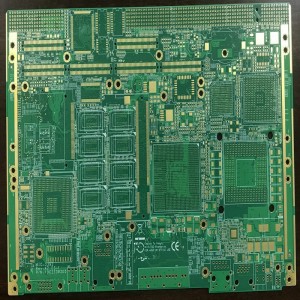

Bari mu gabatar da wasu ilimin kauri na pcb jan karfe.

Copper tsare a matsayin pcb conductive jiki, sauki mannewa zuwa rufi Layer, lalata form kewaye pattern.The kauri daga jan karfe tsare aka bayyana a oz(oz), 1oz = 1.4mil, da kuma talakawan kauri na jan karfe tsare aka bayyana a nauyi da naúrar. yanki ta hanyar dabara: 1oz = 28.35g/ FT2 (FT2 ƙafar murabba'in ce, 1 square ƙafa = 0.09290304㎡).

International pcb jan karfe tsare da aka saba amfani da kauri: 17.5um, 35um, 50um, 70um.Gabaɗaya, abokan ciniki ba sa yin tsokaci na musamman lokacin yin pcb.Kaurin jan ƙarfe na gefe guda da biyu gabaɗaya 35um ne, wato 1 amp jan ƙarfe.Tabbas, wasu ƙayyadaddun ƙayyadaddun allon za su yi amfani da 3OZ, 4OZ, 5OZ... 8OZ, da dai sauransu, bisa ga buƙatun samfur don zaɓar kauri mai dacewa da tagulla.

Gabaɗayan kauri na tagulla na allon PCB guda ɗaya da mai gefe biyu kusan 35um ne, sauran kauri na jan ƙarfe shine 50um da 70um.Kaurin jan karfe na farantin multilayer gabaɗaya 35um ne, kuma kauri na ciki shine 17.5um.Amfani da PCB board kauri na jan karfe yafi dogara da amfani da PCB da sigina ƙarfin lantarki, halin yanzu size, 70% na kewaye hukumar amfani 3535um jan karfe tsare kauri.Tabbas, don na yanzu yana da girman allon kewayawa, kauri na jan karfe kuma za a yi amfani da shi 70um, 105um, 140um (kadan)

Amfani da allo na PCb ya bambanta, amfani da kaurin tagulla shima ya bambanta.Kamar samfuran gama gari da samfuran sadarwa, yi amfani da 0.5oz, 1oz, 2oz;Don yawancin manyan abubuwan yanzu, kamar samfuran ƙarfin lantarki, allon samar da wutar lantarki da sauran samfuran, gabaɗaya amfani da 3oz ko sama shine samfuran jan karfe mai kauri.

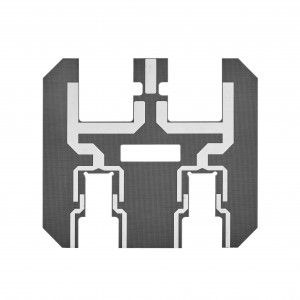

Tsarin lamination na allon kewayawa gabaɗaya shine kamar haka:

1. Shiri: Shirya na'urar laminating da kayan da ake buƙata (ciki har da allunan kewayawa da foils na jan karfe da za a lakafta, latsa faranti, da dai sauransu).

2. Tsabtace jiyya: Tsaftace da deoxidize saman allon kewayawa da foil na jan karfe da za a danna don tabbatar da ingantaccen siyar da aikin haɗin gwiwa.

3. Lamination: Laminating foil na tagulla da allon kewayawa gwargwadon buƙatu, yawanci Layer na allo guda ɗaya da tagulla na tagulla ana jera su daban-daban, daga ƙarshe kuma ana samun allo mai nau'i-nau'i.

4. Matsayi da latsawa: sanya katako mai laminated a kan na'urar latsawa, kuma danna maɓallin kewayawa mai yawa ta hanyar sanya farantin latsawa.

5. Tsarin latsawa: Ƙarƙashin ƙayyadaddun lokaci da matsa lamba, ana matse allon kewayawa da foil ɗin tagulla tare da na'ura mai matsi don a haɗa su tare.

6. Maganin sanyaya: Sanya allon da'irar da aka danna akan dandamalin sanyaya don sanyaya jiyya, ta yadda zai iya kaiwa ga yanayin zafi da matsa lamba.

7.Tsarin aiki na gaba: Ƙara abubuwan da aka adana a saman allon kewayawa, yin aiki na gaba kamar hakowa, shigar da fil, da dai sauransu, don kammala dukkanin tsarin samar da tsarin.

FAQs

Kaurin Layer na jan karfe da aka yi amfani da shi yawanci ya dogara da halin yanzu da ke buƙatar wucewa ta PCB.Matsakaicin kauri na jan ƙarfe shine kusan mil 1.4 zuwa 2.8 (1 zuwa 2 oz)

Matsakaicin kaurin tagulla na PCB akan laminate mai sanye da tagulla zai zama 0.3 oz-0.5oz

Mafi ƙarancin kauri PCB kalma ce da ake amfani da ita don bayyana cewa kaurin allon da'ira ya fi na PCB na al'ada.Matsakaicin kauri na allon kewayawa a halin yanzu shine 1.5mm.Matsakaicin kauri shine 0.2 mm don yawancin allon kewayawa.

Wasu daga cikin mahimman halayen sun haɗa da: mai hana wuta, dielectric akai-akai, ma'aunin asara, ƙarfin juzu'i, ƙarfin juzu'i, zafin canjin gilashi, da yawan kauri ya canza tare da zafin jiki (madaidaicin haɓakar axis Z-axis).

Kayan da aka rufe shine ke ɗaure maƙallan da ke kusa, ko cibiya da Layer, a cikin tarin PCB.Ainihin ayyuka na prepregs shine a ɗaure cibiya zuwa wani cibiya, ɗaure cibiya zuwa Layer, samar da insulation, da kare allon multilayer daga gajeriyar kewayawa.